3D printing technologies

Material overview

according to production technology

Plastics

SLS

Maximum build volume: 950x450x400mm

| Material Name | Used Technology | Material characteristics | Advantages / Benefits |

| PA 12 | SLS | Polyamid (PA) 12i s an engineering plastic which is particularly striking because of its good mechanical properties. At the same time, PA 12 offers high strength and toughness as well as excellent sliding and wear behaviour. These properties make this plastic a particularly good material for robust components. |

|

| PA-GF | SLS | PA-GF is a white, halogen-containing powder, which impresses above all with its high stiffness in combination with good elongation at break. At the same time, PA-GF offers excellent mechanical properties, very smooth surfaces and a high level of detail. |

|

| HST | SLS | HST (fibre-reinforced composite material) combines excellent mechanical strength with high thermal resistance. In addition, this fibre-reinforced composite material offers outstanding rigidity. Typical applications of HST are functional prototypes. |

|

| PA-AL | SLS | Alumide is a mixture of polyamide and aluminium powder, which stands out due to its special metallic look. In addition to this special metal design, components made of Alumide are characterised by high rigidity and good post-processing possibilities. |

|

| TPU | SLS | Thermoplastic polyurethane (TPU) is an elastic and at the same time wear-resistant material. TPU also offers dynamic resistance. |

|

| PP | SLS | This thermoplastic material combines high chemical resistance with good fatigue resistance. In addition, the slightly elastic PP proves to be extremely temperature resistant. |

|

| Flex | SLS | This elastic material is available in the Shore hardnesses A55-75. DuraForm Flex offers dynamic resistance and is also wear resistant. |

|

Multi Jet Fusion (MJF)

Maximum build volume: 380x284x380mm

| Material Name | Used Technology | Material characteristics | Advantages / Benefits |

| PA 12 | MJF | Polyamid (PA) 12 is an engineering plastic which is particularly striking because of its good mechanical properties. At the same time, PA 12 offers high strength and toughness as well as excellent sliding and wear behaviour. These properties make this plastic a particularly good material for robust components. |

|

| Glass reinforced (PA-GF) | MJF | MJF-PA-GF is a thermoplastic filled to 40% with glass beads. Optimum mechanical properties are as much a benefit of this material as a high recycling rate of around 70%. In this way, MJF-PA-GF makes it possible to significantly reduce the unit costs of production. |

|

Selective Absorption Fusion (SAF)

| Material Name | Used Technology | Material characteristics | Advantages / Benefits |

| PA 11 | SAF | PA 11 is usually obtained from castor oil and is an ecologically friendly product. It has better mechanical properties than petrochemically produced PA12: higher ductility, impact strength (notched impact strength), abrasion and fatigue resistance, improved isotropy, better chemical resistance. The temperature resistance of PA11 is comparable to PA12. |

|

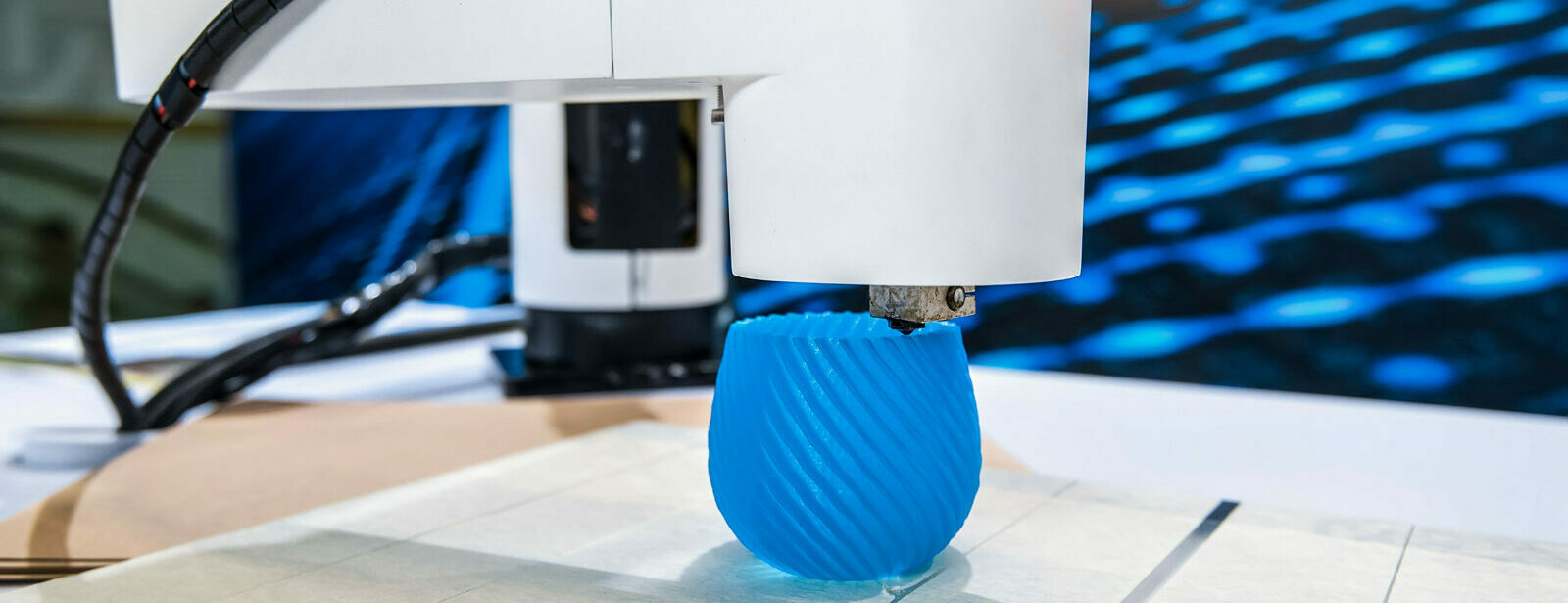

Fused Deposition Modeling (FDM)

Maximum build volume: 914x609x914mm

| Material Name | Used Technology | Material characteristics | Advantages / Benefits |

| PLA | FDM | Polylactide

(PLA), which is mainly known from home 3D printing, is a biocompatible

plastic of high stiffness. At the same time, PLA is an inexpensive

material option made from renewable raw materials. |

|

| PLA-Metal-containing | FDM | Metal-containing PLA combines all the properties of standard PLA with the optical, haptic and electromagnetic advantages of metal. PLA containing metal can be printed in the same way as normal PLA, but the result is of much greater weight. Typical areas of application are figures, jewellery, handicrafts or even props. |

|

| ABS | FDM | ABS (=acrylonitrile-butadiene-styrene) impresses with its great strength and stability. It also offers high durability, good functional properties and is available in various colours. ABS offers a wide range of applications, for example for functional and product samples, as well as in medicine and architecture. |

|

| ABS-ESD7 | FDM | In contrast to common ABS, ABS-ESD7 offers the unique possibility to dissipate electrostatic charges. This material is therefore particularly suitable for electronic products as well as for all areas where electrostatic charges could lead to performance impairments. |

|

| ASA | FDM | The most important advantages of ASA are its UV resistance and its high durability. The mechanical properties of ASA are comparable to those of ABS. |

|

| PETG | FDM | The basic material PET (polyethylene terephthalate) is generally known and very widespread in almost all sectors. For 3D printing, however, the sub-material PETG is usually used. The G stands for "glycol-modified". This modification makes the material clearer, more stable and last but not least easier to print. With regard to its stability, PETG lies between ABS (even more stable) and PLA (less stable). PETG scores points above all for its flexibility, strength, temperature resistance and resilience. On the one hand, it is suitable for visually attractive visible components and on the other hand for components subject to mechanical stress. PETG is used for functional prototypes as well as for coarser threads within components. |

|

| PA 6 | FDM | Polyamide (PA) 6 is an engineering plastic that stands out above all for its good mechanical properties. At the same time, PA 6 offers high strength and toughness, as well as excellent sliding and wear behaviour. These properties make this plastic a good material for robust components. |

|

| PC | FDM | This thermoplastic offers good heat resistance, combined with good mechanical resistance. At the same time, Polycarbonate (PC) impresses with excellent impact and shock resistance. |

|

| PC/ABS | FDM | This material blend of polycarbonate (PC) and acrylonitrile-butadiene-styrene (ABS) combines the strength and heat resistance of PC with the flexibility of ABS. |

|

| ULTEM 9085 | FDM | ULTEM 9085 is a high performance thermoplastic with good chemical resistance. At the same time ULTEM 9085 is permanently flame retardant (according to UL94-V0) and heat resistant up to 153°C. In addition, this material meets the FST safety standards and is particularly suitable for lightweight construction. |

|

| ULTEM 1010 | FDM | ULTEM 1010 is a high performance thermoplastic with good chemical resistance. ULTEM 1010 complies with the food contact certification NSF 51, the biocompatibility standard ISO 10993/USP Class VI, as well as the flame retardancy standard UL94-V0. ULTEM 1010 is heat resistant up to 216°C. |

|

| PETG-CF | FDM | PETG-CF is a material containing carbon fibre. The base material Amphora AM1800 is reinforced with 20% carbon fibres. Therefore, the material is characterized by its stiffness. In addition, PETG-CF is temperature resistant up to 80°C and impresses with a visually very appealing, matt surface. |

|

| TPU (rubbery) | FDM | TPU is a lightweight polyurethane-based plastic with rubber-like properties. This makes TPU particularly suitable for the production of flexible objects. At the same time, TPU impresses with its high impact strength in combination with good chemical resistance. Areas of application include textiles or flexible prototypes. |

|

| ABSi | FDM | ABSi (Acrylonitrile-Butadien-Styrene - BiocompatibleI is an ABS-like thermoplastic with high impact resistance. This material is stiffer and more durable than the standard ABS material and is translucent. For this reason ABSi is ideal for applications where light transmission and flow must be observed, for example in the automotive industry or for prototypes of medical devices. |

|

| PC-ISO | FDM | PC-ISO is a biocompatible FDM thermoplastic that enables engineers to produce prototypes, moulds and products from heat-resistant material for the pharmaceutical, food and medical industries. |

|

| PPSF / PPSU | FDM | PPSU combines strong mechanical performance with high temperature and chemical resistance for demanding applications such as low volume injection moulds, automotive parts in the engine compartment and heat, chemical, plasma and radiation sterilisation. |

|

| GreenTEC | FDM | GreenTEC is a biopolymer specifically designed for high performance applications where high temperature resistance and good mechanical properties are required. Furthermore, the raw material is approved according to FDA, REACH and RoHS standards. |

|

SLA

Maximum build volume: 650x750x550mm

| Material Name | Used Technology | Material characteristics | Advantages / Benefits |

| Xtreme | SLA | Accura's Xtreme material is particularly impressive with its excellent surface quality, good elongation properties, high impact resistance and high stability. In terms of appearance and surface finish, Xtreme corresponds to a durable cast plastic. A typical field of application are master patterns for vacuum casting. |

|

| Resin - LTClear | SLA | LTClear Tough is one of the hardest and most elastic materials in the resin family. LTClear Tough impresses with its high elongation at break, combined with equally high impact resistance. LTClear Tough is particularly suitable for tools/devices, as well as for housings and switching technology. |

|

| ClearVue (transparent) | SLA | ClearVue is a highly clear plastic with excellent moisture resistance. This material is suitable for a wide range of applications where transparency (translucency) is of crucial importance. These would be for example headlights, complex assemblies or fluid flows. |

|

| Resin - Tough | SLA | Tough is a plastic with ABS-like properties, especially in mechanical terms. Tough was developed as an extremely strong and resistant plastic. Therefore, this plastic is a perfect choice, not least for robust, functional prototypes. |

|

| Resin - High Temp | SLA | Especially suitable for components which are exposed to high temperatures. |

|

| ACCURA 25 | SLA | The material ACCUR 25 is convincing due to its high detail resolution and at the same time high bending and impact resistance. In addition, the parts in this material have a smooth surface and can therefore be easily painted. |

|

| NEXT | SLA | This material comes very close to the properties of ABS and therefore has a high strength and hardness. |

|

| Taurus | SLA | When it comes to components with high stability and temperature resistance, the Taurus material is perfect for these applications. |

|

Multi Jet Modelling (MJM)

Maximum build volume: 1000x800x500mm

| Material Name | Used Technology | Material characteristics | Advantages / Benefits |

| VeroClear | MJM | Vero Clear Transparent is a translucent material for PolyJet printing. This synthetic resin-based material combines detailed surfaces with a thin layer structure. Vero Clear Transparent has properties comparable to those of acrylic. |

|

| Vero | MJM | Vero is a PolyJet printing material based on synthetic resin. This material enables particularly accurate components, made of thin layers and with detailed surfaces. |

|

| Agilus30 | MJM | This rubber-like plastic has a Shore hardness of 30A and is available in the basic colour black. The properties of Agilus 30 are similar to those of NBR and EPDM. It is mainly used in the medical field and in the aerospace industry. |

|

| Digital ABS | MJM | DigitalABS is a plastic similar to standard ABS, but is processed using the MJM method. DigitalABS combines high temperature resistance with a high level of detail accuracy. This plastic is particularly suitable for functional designs with multi-material versatility. Another field of application is snap-fit connections at high or low temperatures. |

|

Silicone Additive Manufacturing (SAM)

| Material Name | Used Technology | Material characteristics | Advantages / Benefits |

| Medical Silicone | SAM | Novel, genuine, medical silicone, cured layer by layer by UV light. Precision according to ISO DIN EN 2768-1 m, available in four shore hardnesses: 20A, 35A, 50A and 60A and certified according to: DIN ISO 10993 5 and DIN ISO 10993 10. Applications: functional prototyping, or ready-to-use products, medical applications. |

|

Colorjet-Printing (CJP)

Maximum build volume: 250x380x200mm

| Material Name | Used Technology | Material characteristics | Advantages / Benefits |

| VisiJet PXL | CJP | The material PXL was developed by Visijet especially for the production of realistic, high-resolution full-colour models. Typical fields of application are especially conception models, assemblies or prototypes. ColorBond infiltration is an excellent finish. |

|

Hot-Lithography

Maximum build volume: 200x100x300mm

| Material Name | Used Technology | Material characteristics | Advantages / Benefits |

| Evolution | Hot-Lithography | The all-round performance material for your product development from functional prototypes to the production of entire series in the small and medium series segment. It impresses with its matt surface, excellent haptics and suitability for cutting threads for secure screw connections. |

|

| Evolution FR | Hot-Lithography | The flame-retardant material with UL94 V0 classification. This flame-retardant plastic is a material for the production of small and medium series of flame-retardant final components and for fully functional prototypes in component and product development. |

|

| Precision | Hot-Lithography | The material for precision applications. The resin system specially developed for the manufacture of small components impresses with the highest possible precision combined with excellent material properties. |

|

Binder Jetting (BJ)

Maximum build volume: 1000x1800x700mm

| Material Name | Used Technology | Material characteristics | Advantages / Benefits |

| Quartz sand | BJ | Quartz sand is a raw material that is available in almost unlimited quantities worldwide. In 3D printing, quartz sand allows for economical production. This material combines high thermal resistance with high strength. Quartz sand is particularly suitable for sand casting. |

|

Vacuum Casting

Maximum build volume: 350x350x300mm

| Material Name | Used Technology | Material characteristics | Advantages / Benefits |

| MG 703 (PP/PE similar) | Vacuum Casting | The material has very similar material properties to PP or PE and is therefore ideal for prototype construction if PP or PE is to be used as the final material. |

|

| MG 804 (ABS/PA similar) | Vacuum Casting | The material has very similar material properties to ABS or PA and is therefore ideal for prototype construction if ABS or PA is to be used as the final material. |

|

| PU Casting resin | Vacuum Casting | The PU casting resin is a polyurethane-based resin and is ideally suited for casting prototype parts. |

|

| ProtoFlex | Vacuum Casting | This material is ideal for flexible prototypes which are to be produced by vacuum casting. |

|

Metals

SLM

Maximum build volume: 300x300x350mm

| Material Name | Used Technology | Material characteristics | Advantages / Benefits |

| Steel Corrax (CL91RW) | SLM | The corrosion-resistant tool steel Corrax (CL91RW) offers a high level of corrosion resistance while maintaining high strength. At the same time, Corrax is food-certified and allows good reworking possibilities. |

|

| Martensitic nickel steel (1.2709) | SLM | 1.2709 tool steel is a high strength martensitic nickel steel with excellent tensile strength and toughness. In addition, this steel is particularly low in distortion. |

|

| Stainless steel (1.4404) | SLM | The stainless steel alloy 1.4404 impresses with good corrosion resistance in combination with high conductivity. |

|

| Aluminium (AISi10Mg) | SLM | This aluminium alloy combines high strength with low weight. In addition, this material scores with a high dynamic load capacity. It is used especially in the aerospace industry. |

|

| Inconel (IN625) | SLM | IN625 is a nickel-chromium-iron-molybdenum alloy with exceptional strength, heat resistance and excellent resistance to corrosion and oxidation. |

|

| Inconel (IN718) | SLM | IN718 is a nickel-chromium-iron-molybdenum alloy with exceptional strength, heat resistance and excellent resistance to corrosion and oxidation. |

|

| Stainless steel (1.4542) | SLM | The steel 1.4542 is characterised by high strength and ductility. At the same time, this steel has a high resistance to corrosion and can be sterilised. |

|

| Titan (TiAl6V4) | SLM | Titanium (TiAl6V4) is a metal alloy for highest demands. It convinces by high strength and corrosion resistance. A further advantage is the low density of the material. |

|

Direct Metal Printing (DMP)

Maximum build volume: 273x273x420mm

| Material Name | Used Technology | Material characteristics | Advantages / Benefits |

| Stainless steel(1.4542) | DMP | The steel 1.4542 is characterised by high strength and ductility. At the same time, this steel has a high resistance to corrosion and can be sterilised. |

|

| Aluminium (AISi10Mg) | DMP | This aluminium alloy combines high strength with low weight. In addition, this material scores with a high dynamic load capacity. It is used especially in the aerospace industry. |

|

| Titan (TiA16V4) | DMP | The alloy is particularly suitable for applications with high demands on strength and low weight. In addition, the titanium alloy is characterised by good corrosion resistance. |

|