3D printing technologies

3D-Technologies

and their materials

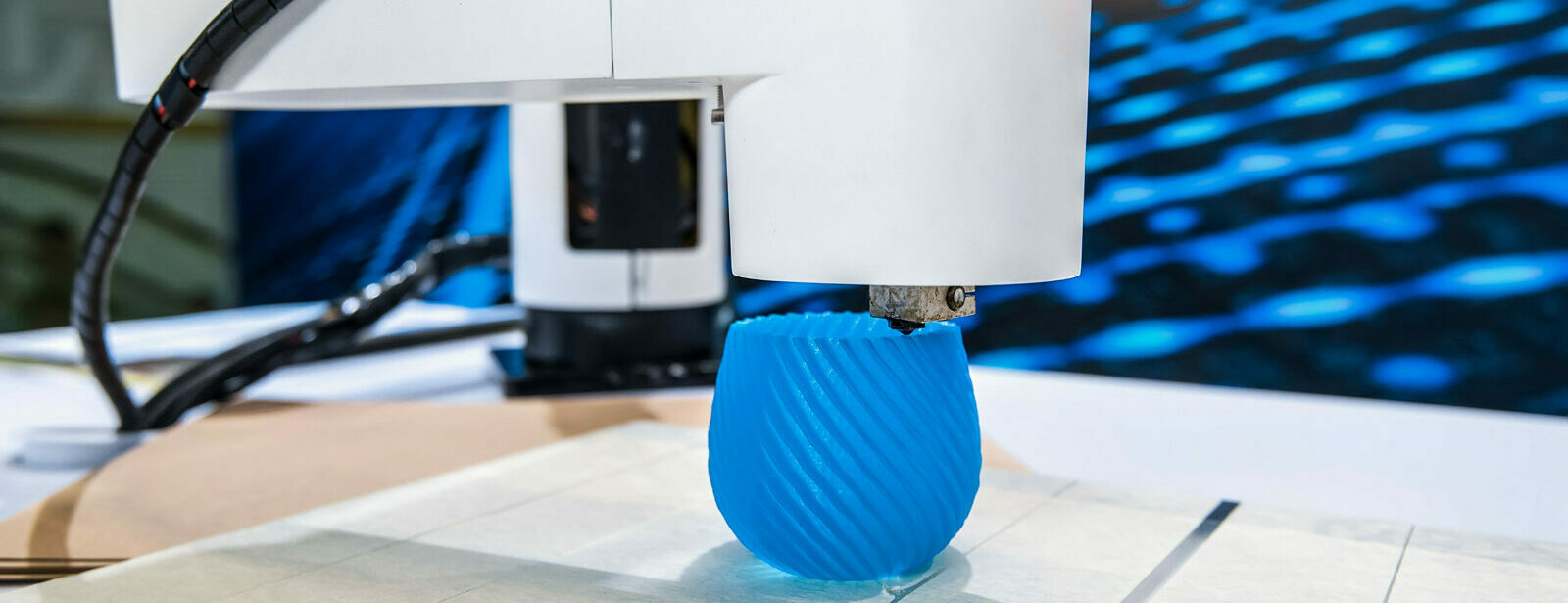

3D printing, also known as additive manufacturing, applies materials such as polymers or metals layer by layer to create individual parts or entire assemblies. The wide variety of technologies and materials available makes it possible to produce thin wall thicknesses as well as complex geometric shapes and fine to transparent surfaces. Rapid prototyping is used to produce prototypes quickly, significantly reducing the time it takes to manufacture various assemblies.

A compact overview of all the technologies we offer and the materials that can be processed:

Materials

Available additive manufacturing technologies for plastics

| Technology | Characteristics | Application area | Application materials |

| SLS Maximum built volume: 950x450x400 | In selective laser sintering, plastic powder is melted layer by layer. |

|

|

| Multi Jet Fusion (MJF) Maximum built volume: 380x284x380 | With the Multi Jet Fusion, a print head is used to print the binder fluid into a powder bed of plastic. The thermally conductive liquid binds the plastic powder. |

|

|

| Selective Absorption Fusion (SAF) Maximum built volume: 315x208x293 | Powder particles are fused in discrete layers using the Big WaveTM powder management system. Uniform heating and part consistency are ensured with this process. By using piezo-electric print heads, both fine details and large areas can be produced without compromising throughput. |

|

|

| Fused Deposition Modeling (FDM) Maximum built volume: 914x609x914 | In Fused Deposition Modeling (FDM) or Fused Filament Fabrication (FFF), wire-shaped plastic is melted and applied layer by layer. |

|

|

| SLA Maximum built volume: 650x750x550 | In the SLA process, liquid plastics (photopolymers) are cured by a UV laser. |

|

|

| Multi Jet Modeling (MJM) Maximum built volume: 1000x800x500 | In MultiJet Modelling (MJM), a photopolymer, i.e. light-sensitive plastic is applied to a platform through several nozzles (hence the name). There this plastic is immediately cured. |

|

|

| Silicone Additive Manufacturing (SAM) Maximum built volume: 130x75x120 | Similar to SLA and DLP, SAM works by selectively exposing silicone to a light source to form very thin solid layers that are layered on top of each other to form the geometry of the part. |

|

|

| ColorJet Printing (CJP) Maximum built volume: 250x380x200 | The full-colour 3D printer builds individual layers on the basis of the digital CAD file and prints the fine polyamide powder in layers from bottom to top. A binder-containing ink is used for this purpose, which specifically bonds the powder. |

|

|

| Hot-Lithography Maximum built volume: 200x100x300 | The core of the technology is a specially developed and patented heating and coating mechanism, which can process even highly viscous resins and pastes at a working temperature of up to 120°C safely and with maximum precision. |

|

|

| Binder Jetting (BJ) Maximum built volume: 1000x1800x700 | In binder jetting sandis bonded in layers by a binder. |

|

|

| Vacuum Casting (Early Adopter) Maximum built volume: 350x350x300 | Reproduction in a silicone rubber mould of a master model (e.g. by 3D printing or stereolithography) previously produced by various methods. |

|

|

Metals

Available additive manufacturing technologies for metals

| Technologie | Eigenschaft | Einsatzgebiet | Verwendbare Materialien |

| SLM Maximum built volume: 300x300x350 | In selective laser melting, metal powder is melted layer by layer by a laser. |

|

|

| Direct Metal Printing (DMP) Maximum built volume: 273x273x420 | A high-precision laser is directed at metal powder particles, thus building up the part layer by layer. |

|

|